Prospero Build Diary - Part Three

What's really going to make this case striking is the most audacious part of the plan - a 5" plasma globe that projects from the bottom front of the case, and sits there with swirling, glowing plasma filaments while the computer is on. Here's a basic plasma globe from Spencer's with the plastic base already removed, in it's styrofoam package for safekeeping: A plasma globe works by bullshit bullshit high voltage AC field bullshit bullshit through low pressure gas in a glass sphere bullshit bullshit bullshit. Therefore I need to make sure that all that current isn't grounding through my case; not only would that be bad (I presume) for the stuff in my computer, but all the cool blue filaments wouldn't go anywhere but to the parts of the globe that were in contact with the case. (Pretty quickly the glass would get hot enough to melt, in contact with a conductor like that.) Therefore I fabricated a plexiglass mounting plate to hold the globe in place:

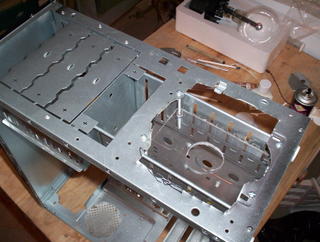

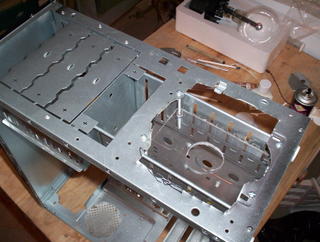

A plasma globe works by bullshit bullshit high voltage AC field bullshit bullshit through low pressure gas in a glass sphere bullshit bullshit bullshit. Therefore I need to make sure that all that current isn't grounding through my case; not only would that be bad (I presume) for the stuff in my computer, but all the cool blue filaments wouldn't go anywhere but to the parts of the globe that were in contact with the case. (Pretty quickly the glass would get hot enough to melt, in contact with a conductor like that.) Therefore I fabricated a plexiglass mounting plate to hold the globe in place:

The plate is held in place by four long bolts. I used tin snips to cut a big enough hole out of the front of the case. If the plexiglass plate looks different below, that's because its a different plate. I had to cut that thing about three times. "Measure none, cut thrice." That's my motto.

The plate is held in place by four long bolts. I used tin snips to cut a big enough hole out of the front of the case. If the plexiglass plate looks different below, that's because its a different plate. I had to cut that thing about three times. "Measure none, cut thrice." That's my motto.

The glass globe sits snugly in the socket in the plate, not touching any of the metal case. Just to be sure I'm going to line the case's hole with an insulating gasket just to prevent any chance of conduction through the case.

The glass globe sits snugly in the socket in the plate, not touching any of the metal case. Just to be sure I'm going to line the case's hole with an insulating gasket just to prevent any chance of conduction through the case.

And, below, I've tried to mark out on the bezel where I'm going to have to cut the hole out.

And, below, I've tried to mark out on the bezel where I'm going to have to cut the hole out.

That's the real tricky part. This is the hole that has to look nice and fit snugly; the globe will, to some extent, be resting on the plastic bezel for support. The globe is almost too big. It's gonna be impressive as hell, assuming I don't crash my chairleg into it one day, and a surefire hit at the next time I'm at a lan party, which will be never, I'm sure.

That's the real tricky part. This is the hole that has to look nice and fit snugly; the globe will, to some extent, be resting on the plastic bezel for support. The globe is almost too big. It's gonna be impressive as hell, assuming I don't crash my chairleg into it one day, and a surefire hit at the next time I'm at a lan party, which will be never, I'm sure.

Well, that's as far as I got today. The problem is I'm not sure how to cut a nice, symmetrical hole in the fairly flimsy plastic bezel. I only have one so it has to be right the first time. No do-overs. Power tools are out, I think, which leaves cutting the thing with a hacksaw. What I need is a scratch bezel to practice on. Guess I'm going dumpster diving.

A plasma globe works by bullshit bullshit high voltage AC field bullshit bullshit through low pressure gas in a glass sphere bullshit bullshit bullshit. Therefore I need to make sure that all that current isn't grounding through my case; not only would that be bad (I presume) for the stuff in my computer, but all the cool blue filaments wouldn't go anywhere but to the parts of the globe that were in contact with the case. (Pretty quickly the glass would get hot enough to melt, in contact with a conductor like that.) Therefore I fabricated a plexiglass mounting plate to hold the globe in place:

A plasma globe works by bullshit bullshit high voltage AC field bullshit bullshit through low pressure gas in a glass sphere bullshit bullshit bullshit. Therefore I need to make sure that all that current isn't grounding through my case; not only would that be bad (I presume) for the stuff in my computer, but all the cool blue filaments wouldn't go anywhere but to the parts of the globe that were in contact with the case. (Pretty quickly the glass would get hot enough to melt, in contact with a conductor like that.) Therefore I fabricated a plexiglass mounting plate to hold the globe in place: The plate is held in place by four long bolts. I used tin snips to cut a big enough hole out of the front of the case. If the plexiglass plate looks different below, that's because its a different plate. I had to cut that thing about three times. "Measure none, cut thrice." That's my motto.

The plate is held in place by four long bolts. I used tin snips to cut a big enough hole out of the front of the case. If the plexiglass plate looks different below, that's because its a different plate. I had to cut that thing about three times. "Measure none, cut thrice." That's my motto. The glass globe sits snugly in the socket in the plate, not touching any of the metal case. Just to be sure I'm going to line the case's hole with an insulating gasket just to prevent any chance of conduction through the case.

The glass globe sits snugly in the socket in the plate, not touching any of the metal case. Just to be sure I'm going to line the case's hole with an insulating gasket just to prevent any chance of conduction through the case. And, below, I've tried to mark out on the bezel where I'm going to have to cut the hole out.

And, below, I've tried to mark out on the bezel where I'm going to have to cut the hole out. That's the real tricky part. This is the hole that has to look nice and fit snugly; the globe will, to some extent, be resting on the plastic bezel for support. The globe is almost too big. It's gonna be impressive as hell, assuming I don't crash my chairleg into it one day, and a surefire hit at the next time I'm at a lan party, which will be never, I'm sure.

That's the real tricky part. This is the hole that has to look nice and fit snugly; the globe will, to some extent, be resting on the plastic bezel for support. The globe is almost too big. It's gonna be impressive as hell, assuming I don't crash my chairleg into it one day, and a surefire hit at the next time I'm at a lan party, which will be never, I'm sure.Well, that's as far as I got today. The problem is I'm not sure how to cut a nice, symmetrical hole in the fairly flimsy plastic bezel. I only have one so it has to be right the first time. No do-overs. Power tools are out, I think, which leaves cutting the thing with a hacksaw. What I need is a scratch bezel to practice on. Guess I'm going dumpster diving.

0 Comments:

Post a Comment

<< Home